reliable and cost-effective predictive maintenance of electric motors

Low voltage

Further drive technology

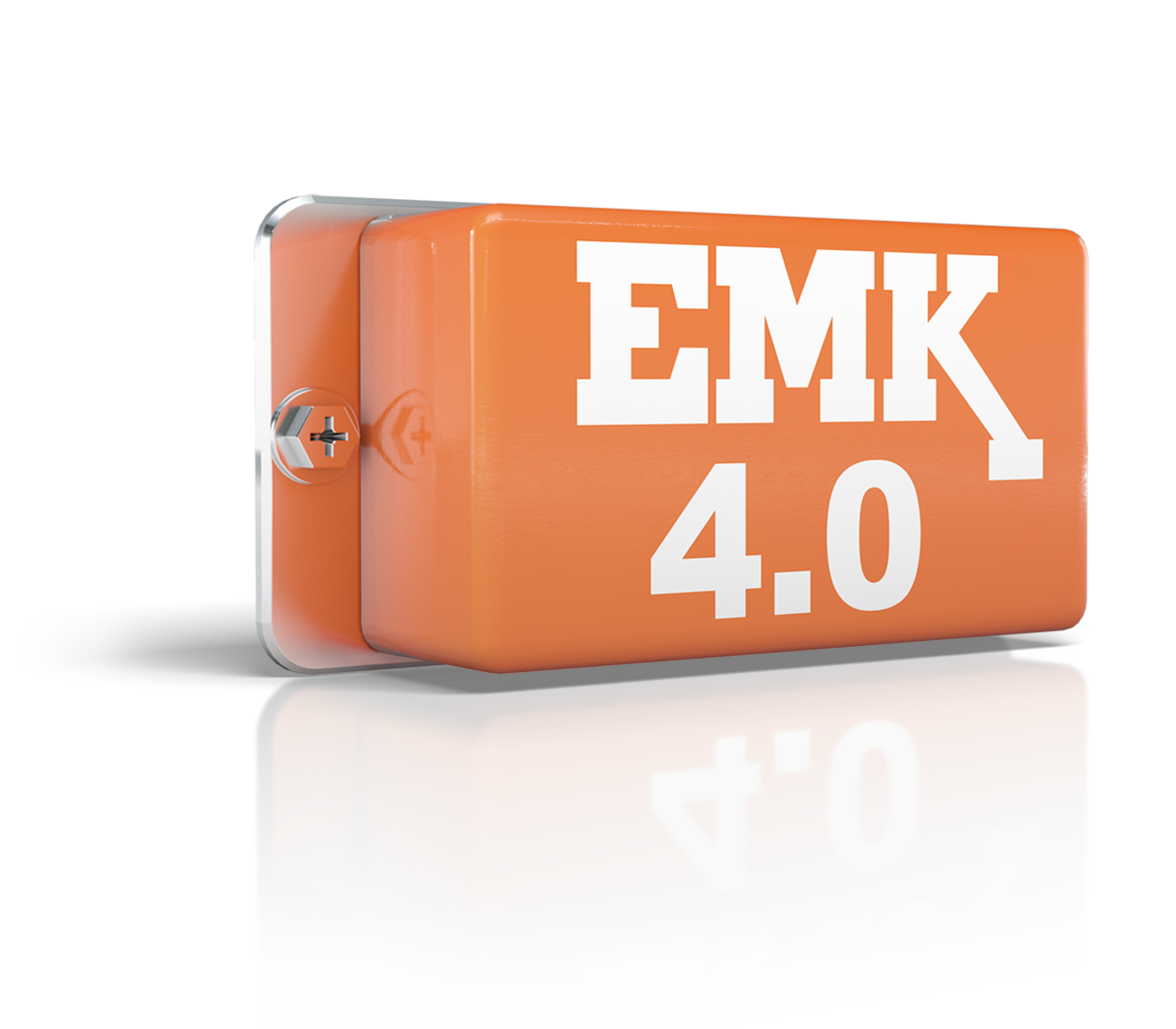

EMK 4.0 Motor sensor

THE INTELLIGENT MOTOR SENSOR

Areas of application and quality assurance

The central function of the EMF 4.0 is monitoring and the resulting error detection. Vibration parameters such as bearing condition and unbalance, temperature, speed and electrical parameters of the motor are monitored.

This data is sent to the secure EMK 4.0 Cloud in twenty minute intervals. Comprehensive algorithms analyse the data in real time to detect problems at an early stage. The information can be accessed via a web platform or smartphone app. As soon as EMK 4.0 detects an error, you will be informed immediately by E-mail or Push notification.

You immediately recognise how urgent the problem is and in which part of the motor it is in.

Specified for you

Your advantages at a glance

Functionality:

- Monitoring

EMF 4.0 makes it possible to continuously monitor all motors in the production process in a simple way. - Easy installation

Plug & Play. EMK 4.0 can be installed on motors of a wide range of makes within a few minutes.

- Wireless communication

The sensor works with a WLAN connection and is powered by AA batteries. - Error detection

EMK 4.0 displays the current status of your motor. In the event of an error, you will be informed by e-mail or push notification via your smartphone.

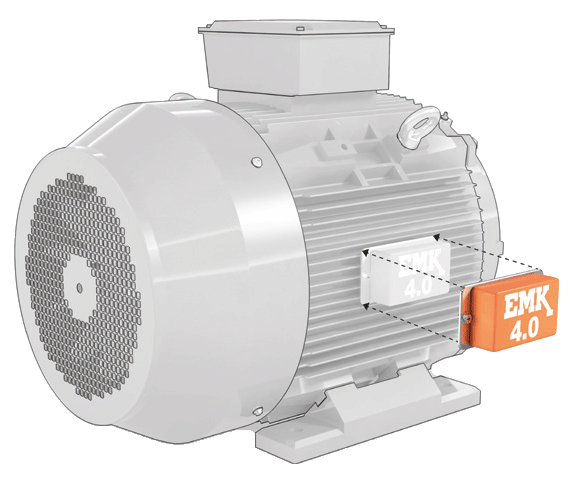

Installation

Installation of the EMK 4.0 is quick and easy via fastening clips on the cooling fins of the motor housing. The sensor can be attached while the motor is running. Thanks to wireless WLAN connection, there is no need for complex wiring.

ERROR DETECTION

EMF 4.0 can detect the following problems at an early stage:

- Eccentricity

- Cooling system

- Loose foot mounting or structural problems

- Performance

- Power supply

- Stator winding

- Rotor imbalance

- Bearing damage

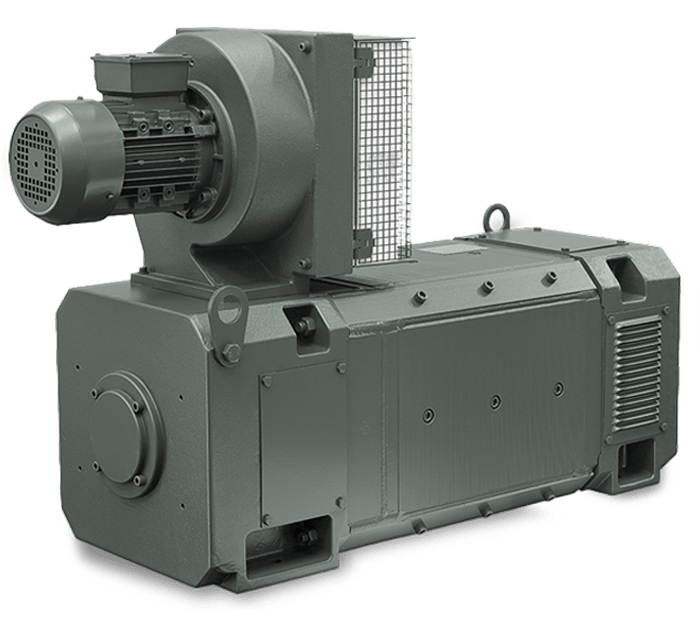

Direct current motors

AVAILABLE EX STOCK UP TO 1,650 KW

20 - 2.500 kW

Power ranges for direct current motors

Areas of application and quality assurance

Our direct current drives reliably fulfil their task for the most diverse applications in drive, energy or process technology. Whether it is the drive of a cable car, in a rolling mill or in a printing company. Our direct current motors run continuously for you.

Specified for you

Your advantages at a glance

MADE BY EMZ

EMZ offers an in-house brand “made by EMZ” for direct current motors. In the design process, we place particular emphasis on high quality and a good price-performance ratio.

OTHER BRANDS

Thanks to our large purchasing volume, we are able to offer you other branded products at attractive prices. EMZ distributes DC motors from leading manufacturers such as Siemens, ABB or TT-Electric.

Modifications according to customer requirements:

We modify DC motors for you in our in-house specialist workshop. Another option is factory production according to customer requirements. Flexibility and individuality:

- for winding protection

- bearing/lubrication

- heating and ventilation

- colours/painting

- assembly technology (forced ventilation, incremental encoders, tachogenerators)

- mechanical design/protection class

- motor connection/terminal box

EMZ bietet ein hauseigenes Markenfabrikat „made by EMZ“ für Gleichstrommotoren an.

Matching our drive technology we offer e.g. our EMK motors and frequency converters.

Contact person low voltage