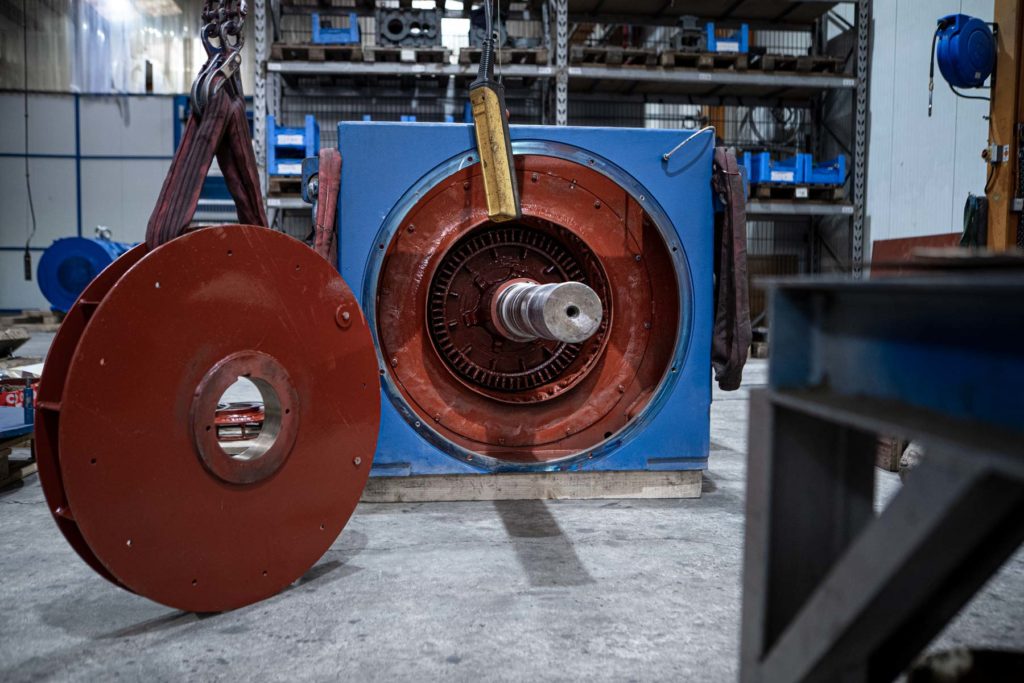

All drives in the high voltage, low voltage and DC range are subjected to individual overhauls in our modern workshops by our qualified specialist staff. n addition, we conscientiously repair geared motors, submersible pumps, transformers and servo motors in our factory.

Serviceportfolio

qualified service personnel

m2 workshop area

tonnes crane system

tonnes balance bench, three metre bed length

volt large machines test bay

SERVICE, REPAIR AND OVERHAUL

In our modern workshops, we carry out overhauls for all drives in the high voltage, low voltage and DC range. Furthermore, we have the possibility to repair geared motors, submersible pumps, transformers & servo motors in our factory.

Services

- High-pressure cleaning of winding and machine

- Winding drying in an air circulated furnace

- Testing of all electrical components

- Testing of the mechanical machine parts

- Inspection of the water coolers, cleaning and reconditioning including pressure testing

- In-house facility for painting

- Sandblasting cleaning of the machine or individual components

- Moisture and termite protection for windings

- Testing of the machine according to EN 60034 and VDE regulations in the test bay

- Balance bench check

- Rewindings of stator and rotor

MAINTENANCE

Competent EMZ service staff are of course also available for maintenance work on your machines. Our preventive maintenance services increase and ensure the service life of your drives and systems.

Motor maintenance:

- Removal and installation of machines

- New bearings

- Re-lubrication of rolling bearings

- Oil change for plain bearing machines

- Inspection and replacement of carbon brush holders

- Inspection and replacement of carbon brushes

- Cleaning of slip ring chamber

- Cleaning and smoothing of slip rings and collectors

- Optimisation of carbon brushes

- Cleaning of cooling elements

- Retrofitting and modifications of systems

DIAGNOSIS

In our in-house test bay, we carry out all measurements and examinations in accordance with EN 60034 and VDE regulations. For machine diagnostics, our qualified specialists from the service team are available on site.

Diagnostics in the factory's own testing bay:

- Laser-assisted alignment

- Vibration analysis

- Determination of the polarisation index (PI index)

- Bar breakage test on three-phase squirrel cage motors

- Iron-cladding test on laminations

- Noise measurement

- Operational balancing

- Determination of magnetic centre and axial play

- Concentric running tests of collectors and slip rings

- Measurements of brush contact pressure

- Testing and adjustment of the neutral zone

- Testing of tacho machines and incremental encoders

- Checking of air volume and flow velocity in the cooling circuit

MODIFICATION

EMZ will carry out modifications and conversions on your machine for you. Our service team will advise you extensively beforehand – be it on converter drives, temperature or vibration monitoring.

Modification options:

- Change of design

- Change of protection class

- Attachment of oscillation generators

- Attachment of speed and rotation direction sensors

- Mounting of surge arresters

- Mounting of standstill heaters

- Mounting of temperature sensors for any measuring sites

- Mounting of forced cooling fans

- Mounting of brakes

- Adjustment of shaft height

- Manufacture of special flanges

- Modification of the cooling method (e.g. conversion of the heat exchanger)

- Fitting of switches and contactors

- Changing the direction of rotation

QUALITY ASSURANCE IN THE TESTING BAY

In the EMZ test area, all measurements and examinations are carried out in accordance with the EN 60034 standards. Our qualified specialists from the service team are available on site for machine diagnostics.

Analyses and testing:

- Complete no-load tests according to EN 60034 up to 6000 kW

- Recording of the no-load and short-circuit characteristics

- Vibration analysis

- Determination of the polarisation index (PI index)

- Bar breakage test on three-phase squirrel cage motors

- Iron-cladding test on laminations

- Sinusoidal feed-in of the test motors via synchronous generator and matching transformers

- Noise measurement

- Operational balancing

- Determination of magnetic centre and axial play

- Concentric running tests of collectors and slip rings

- Measurements of brush contact pressure

- Checking of air volume and flow velocity in the cooling circuit

Acceptances in load run

On request, complete load run acceptance tests can be carried out for all motors. Depending on the torque of the machines to be tested, the load measurement is carried out with a direct load on the motor or alternatively with a partial load measurement in accordance with EN 61986.

EMZ test bay for large motors in data:

- Motor generator set: 2600kVA

- Maximum power at no load: 6000 kW

- Maximum weight of the test motor: 20 tons

- Test area (clamping plates): 8 x 3.4 cm

- Weight of clamping plates: 34 tonnes

- Sinusoidal feed-in of the test motors via synchronous generator and matching transformers

- Available voltage ranges: Low voltage – 400V and 690 volts, medium voltage – 3,300, 4,160, 5,500, 6,000, 6,600, 10,000, 11,000, 13,200 volts.

- Available frequencies: 16 2/3 Hz, 50 Hz, 60 Hz

Available voltage ranges:

- Low voltage – 400V and 690 volts

- Medium voltage – 3,300, 4,160, 5,500, 6,000, 6,600, 10,000, 11,000, 13,200 volts

- Available frequencies: 16 2/3 Hz, 50 Hz, 60 Hz

FOR YOU ON SITE

Worldwide service

Since 1952, EMZ has been a reliable and competent partner in drive technology for our customers worldwide. And our Service is no exception. Via our specially set up EMZ emergency number, our qualified team offers you around-the-clock fast and direct support in all service issues.

Plant shutdown or an emergency?

Give us a call!

With our emergency service we are available for you 365 days, 24 hours!

WE TAKE MAINTENANCE AND SERVICING TO A NEW LEVEL!

EMZ SHARE not only increases your plant availability, but is also able to reduce machine downtimes and increase the overall plant capacity of your production. Our video remote support is device-independent and supports all end devices – from desktop PCs and laptops to tablets, smartphones and data glasses. If required, we will send you one of our realwear data glasses to experience the benefits of augmented reality first-hand.

And the best thing is: You have both hands free to work! In addition to the advantage of saving on travel costs, you also have immediate access to the know-how of our qualified employees. In addition, we can create work plans/work flows for you so that you can be sure to always do the right thing. Documentation and technical descriptions can be made directly accessible via QR code on the machines we supply and are available at the machine location without any time delay.

Experience Full HD Remote Support at an unprecedented level! Get your information now at

Contact Service & Maintenance